Description

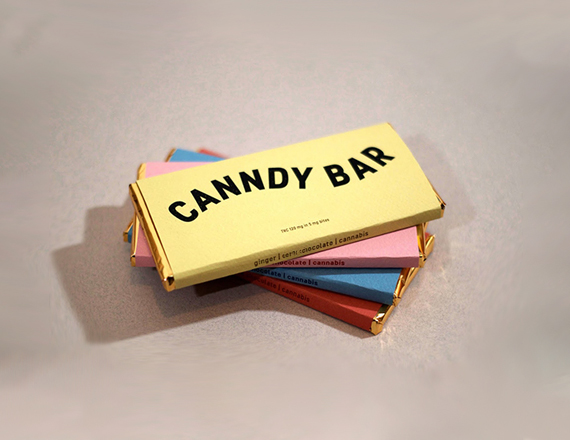

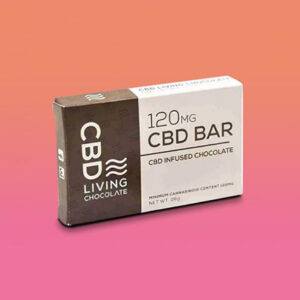

Candy Bar Packaging

Are you looking for a unique and effective way to package your candies, making them a standout on store shelves or as a memorable gift? Look no further than Custom Packaging Supplier’s Candy Bar Packaging! Our premium packaging solution is designed to protect, preserve, and elevate your product while providing an unboxing experience that will leave customers in awe.

Features

Our Candy Bar Packaging offers the following features:

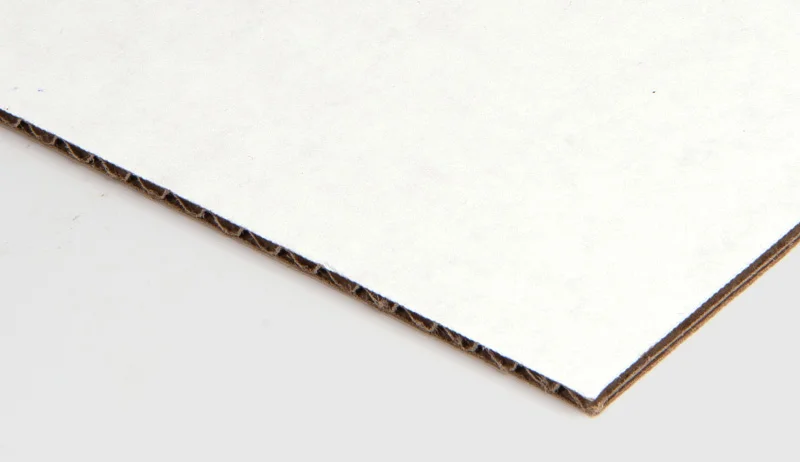

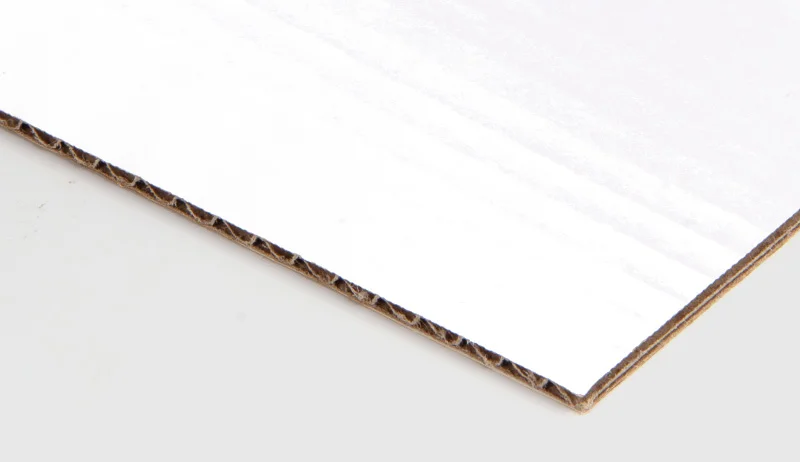

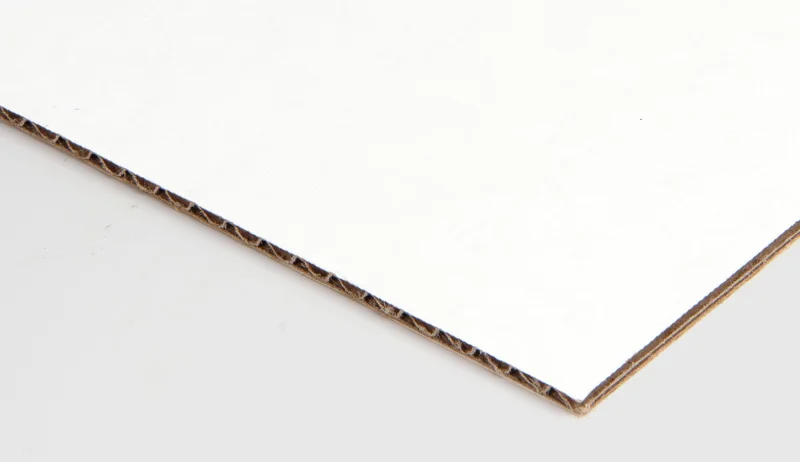

- Innovative, rigid cardboard design for maximum protection against damage

- Customizable printing options for brand logos, colors, and designs

- Variety of size options to fit your candy bars perfectly

- Reliable, eco-friendly materials for a sustainable packaging solution

- Secure closure system for easy opening and re-closing

Benefits

By choosing our Candy Bar Packaging, you’ll enjoy numerous benefits that will take your business to the next level:

- Enhanced brand recognition and reputation through unique packaging

- Increased customer satisfaction with a premium, protection-driven packaging solution

- Competitive edge in the market with a distinctive, attention-grabbing packaging design

- Reduced waste and environmental impact with eco-friendly materials

- Cost-effective solution for a wide range of candy bar sizes and quantities

Materials</hassistant

(h2>Materials

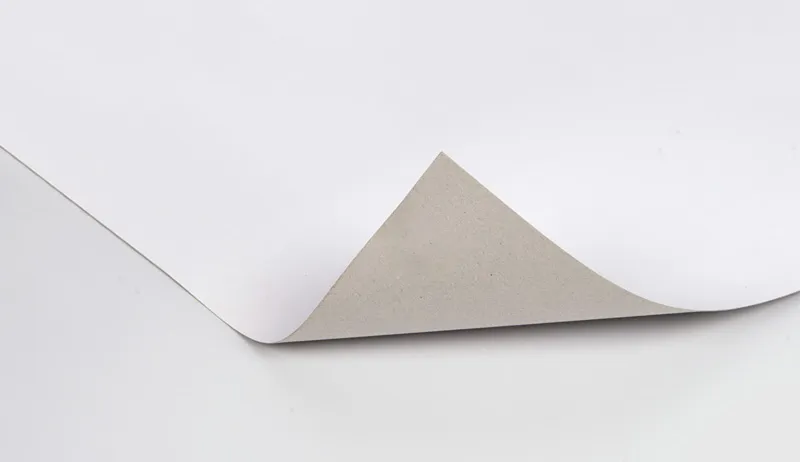

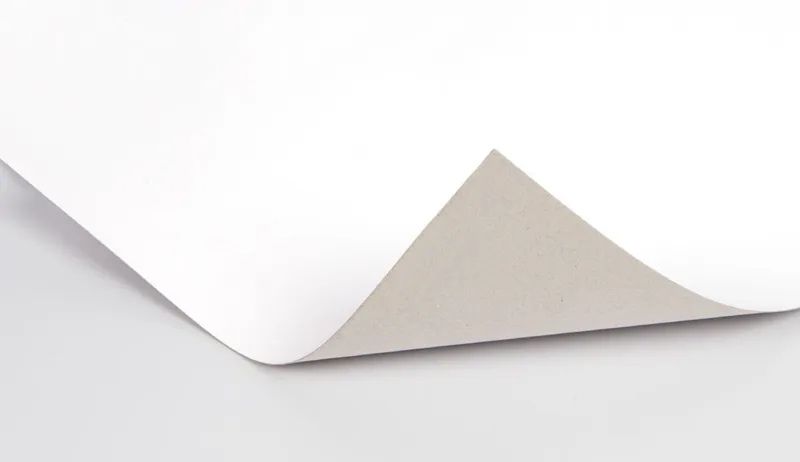

Custom Packaging Supplier uses high-quality, rigid cardboard and eco-friendly materials for our Candy Bar Packaging, ensuring durability, protection, and eco-friendliness. Our materials are carefully selected to meet the needs of your candy bars, offering:

- Cardboard and kraft materials for maximum protection and customization options

- Eco-friendly inks, dyes, and coatings for sustainable, non-toxic packaging

- Food-grade materials, carefully selected to meet the demands of the candy bar industry

Use Cases

Our Candy Bar Packaging is versatile and can be used in various settings and scenarios, including:

- Packaging and gifting for special occasions, holidays, and events

- Protecting and shipping candy bars to stores, distributors, or online customers

- Retail packaging for store displays, shelf sales, and impulse purchases

Customization</hassistant

Customization

At Custom Packaging Supplier, we understand that every business or brand is unique, which is why we offer a range of customization options for our Candy Bar Packaging. Our services include:

Printing Options

Our state-of-the-art printing technology allows us to reproduce even the most intricate designs, logos, and colors onto our packaging materials. Choose from a variety of printing methods, including

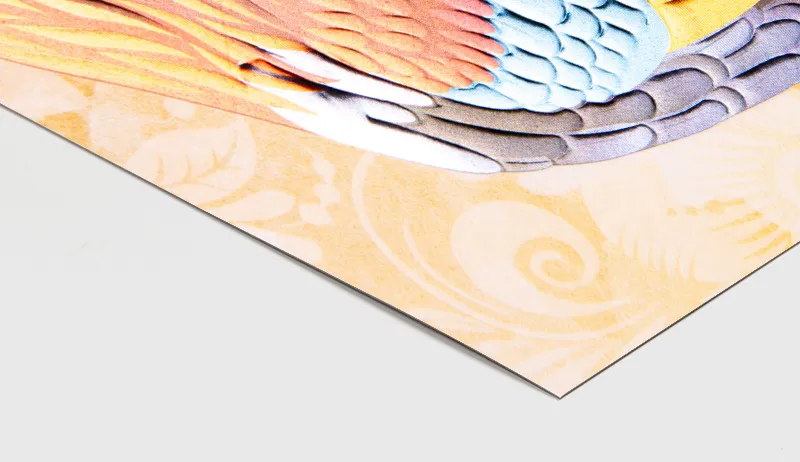

- Full-color digital printing for vibrant, photo-realistic images

- Spot-color printing for sharp, detailed reproduction of logos and graphics

Finishing Touches</hassistant

Finishing Touches

To add an extra layer of detail to our Candy Bar Packaging, we offer a range of finishing touches, including:

- Lamination for added protection and durability

- Embossing or debossing to create textured, dimensional designs

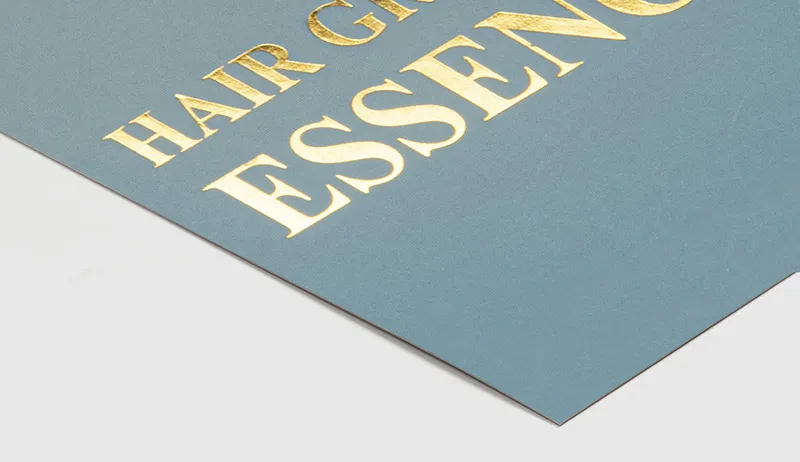

- Foil stamping for a luxurious, metallic finish

- Varnishing or glossy coating for a premium, high-gloss appearance

Why Choose Us

When you choose Custom Packaging Supplier’s Candy Bar Packaging, you’re not just getting a product – you’re partnering with a team of packaging experts dedicated to helping you succeed. Here’s why:

- Years of experience in the packaging industry, ensuring reliable, high-quality products

- Personalized service and support to meet your unique business needs

- Competitive pricing and flexible payment options for easy budgeting

- Environmental sustainability and eco-friendliness in our packaging materials and practices

At Custom Packaging Supplier, we’re committed to providing the best packaging solutions for our customers. Our Candy Bar Packaging is designed to exceed your expectations, delivering unparalleled protection, branding, and unwrapping experiences. Trust our team to help you take your business to the next level – contact us today to learn more!

At Custom Packaging Supplier, we offer a quick turnaround time of just 8–10 business days, ensuring your packaging is delivered on time without hassle. With low minimum order quantities starting at just 100 boxes, we make it easy and cost-effective for businesses of all sizes to get started. Our in-house design experts are here to help you create eye-catching, fully customized packaging for your Industry or any other product you need packed to perfection.

Customer satisfaction is our top priority. That’s why we provide 24/7 support to guide you every step of the way—from design advice and price quotes to order placement and delivery updates. Contact us anytime through live chat, drop us an email at sales@custompackagingsupplier.com, or call us directly at +1 (970) 333 5485. Trust Custom Packaging Supplier to deliver the quality, speed, and support your brand deserves.

Reviews

There are no reviews yet.