Description

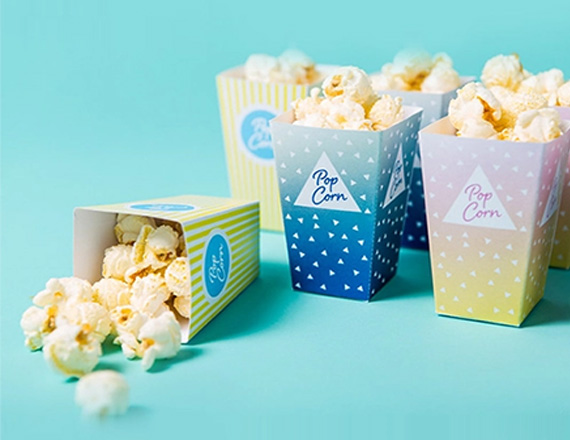

Custom Packaging Boxes for Popcorn

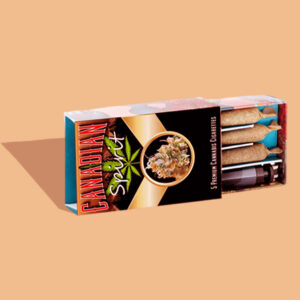

Are you looking for a unique and effective way to package your gourmet popcorn for gift-giving, retail sales, or shipping? Look no further than our Custom Popcorn Boxes! At Custom Packaging Supplier, we understand the importance of presenting your product in a way that showcases its quality and craftsmanship. That’s why we offer a range of custom packaging solutions tailored to the unique needs of the popcorn industry.

Features

Our Custom Popcorn Boxes are designed with durability and functionality in mind. Some of the key features include:

- Sustainable materials: Our boxes are made from 100% recycled kraft cardboard, making them eco-friendly and affordable.

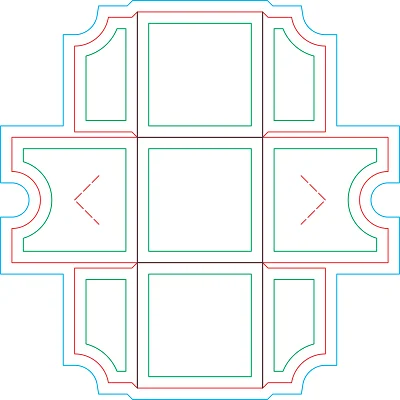

- Custom sizes: We offer a range of standard sizes, as well as custom sizes to fit your specific needs.

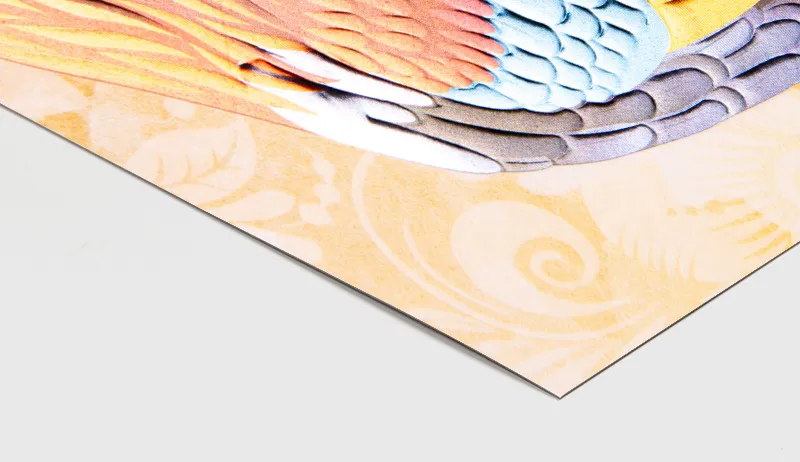

- Printable surface: Our boxes feature a printable surface, allowing you to add your logo, branding, and marketing messages.

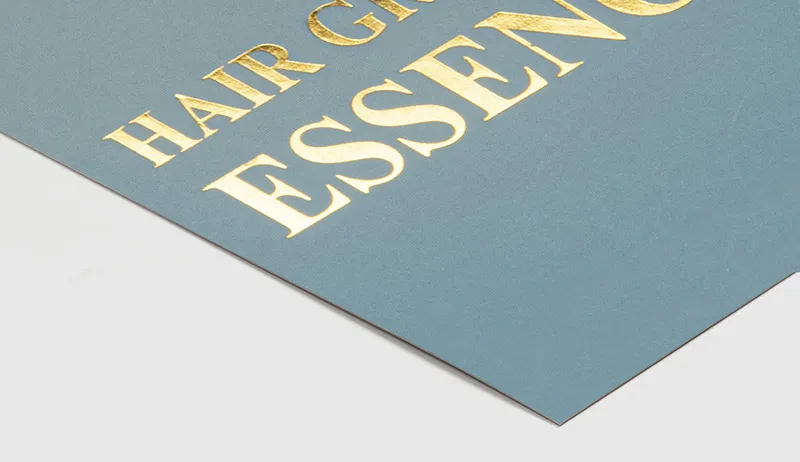

- Finishing options: We offer a variety of finishing options, including spot varnishing, foil stamping, and embossing, to give your packaging a professional touch.

Benefits

By choosing our Custom Popcorn Boxes, you’ll enjoy a range of benefits that will take your business to the next level. Some of the key advantages include:

- Enhanced customer experience: Our custom boxes provide a premium, high-end look that will make your product stand out on store shelves and online.

- Increased brand visibility: With our printable surface, you can promote your brand and marketing messages to customers and potential customers.

- Protection and preservation: Our boxes are designed to provide superior protection and preservation of your popcorn, keeping it fresh and flavorful.

- Cost-effective: Our custom boxes offer a cost-effective solution for packaging, as you only pay for what you need and can easily reorder as needed.

Materials

Our Custom Popcorn Boxes are made from high-quality materials designed to provide durability and protection for your product. Some of the materials we use include:

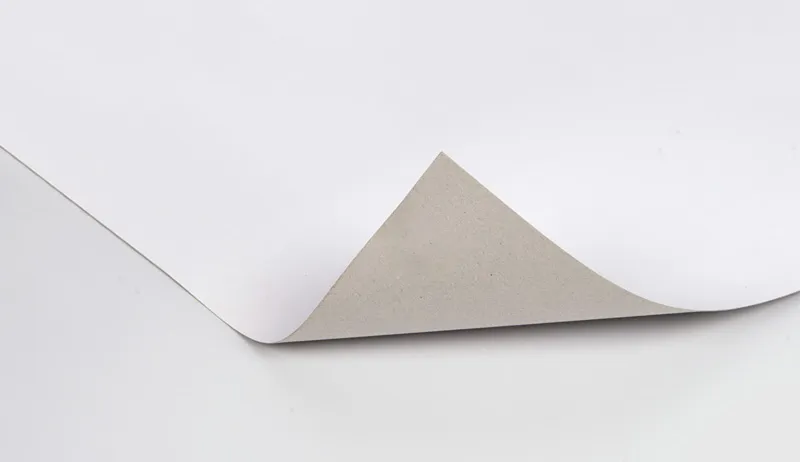

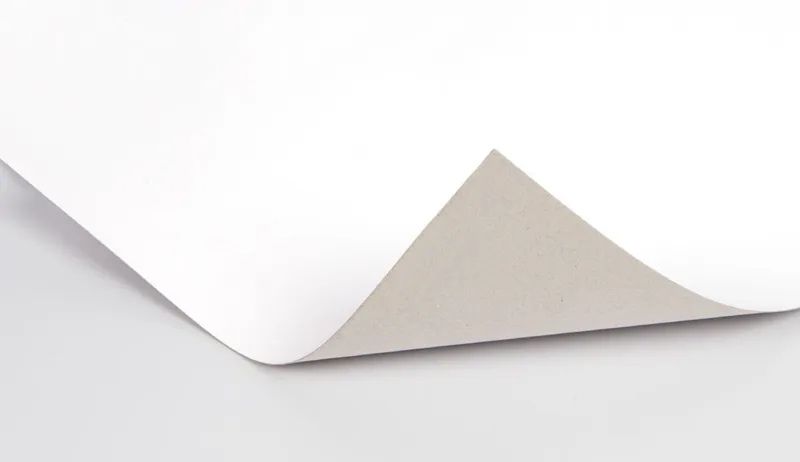

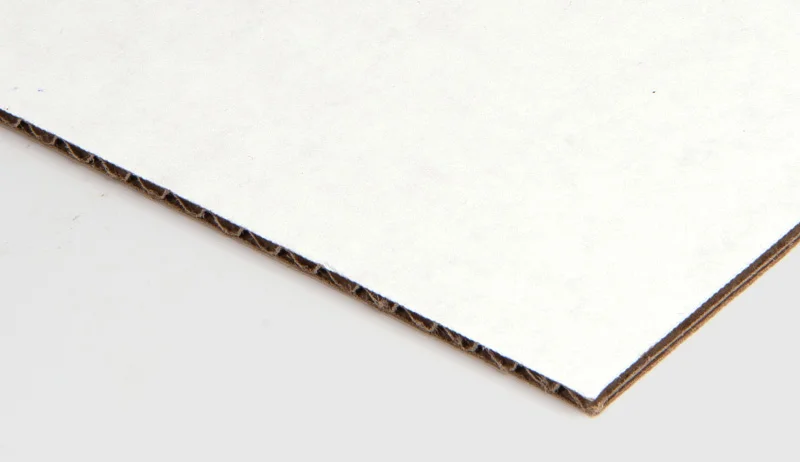

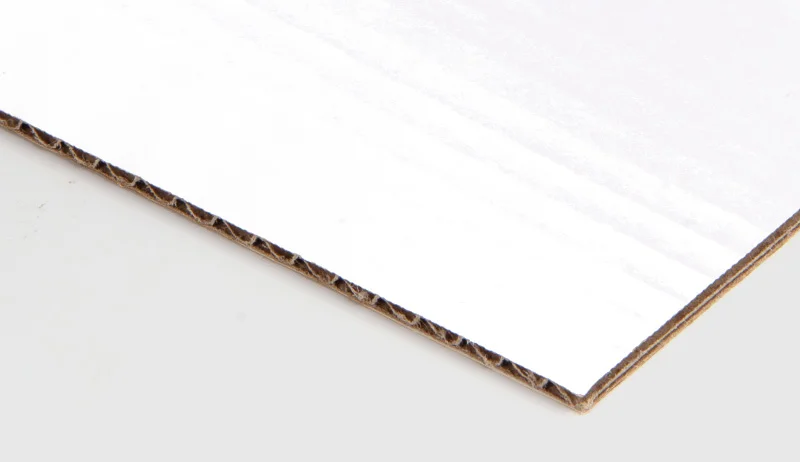

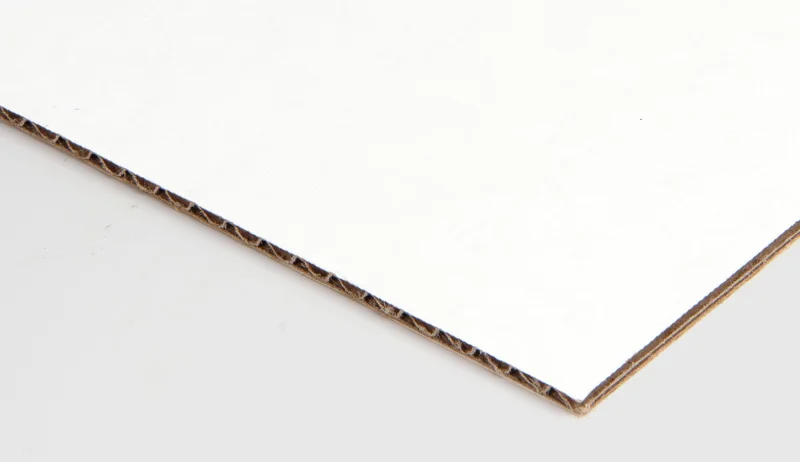

- Cardboard: Our standard material, made from 100% recycled kraft cardboard.

- Rigid cardboard: For added protection and structure, our rigid cardboard material is a great option.

Use Cases

Our Custom Popcorn Boxes are versatile and can be used in a variety of ways. Some of the common use cases include:

- Gift-giving: Perfect for gifting large quantities of popcorn to friends, family, or coworkers.

- Store displays: Showcase your popcorn in an attractive and eye-catching way at your store or retail location.

- Shipping: Safely and securely ship your popcorn products to customers and retailers.

Customization

At Custom Packaging Supplier, we understand that every business is unique, which is why we offer customization options to fit your specific needs. Some of the customization options we offer include:

- Printing: Add your logo, branding, and marketing messages to your boxes.

- Finishing: Choose from a range of finishing options, including spot varnishing, foil stamping, and embossing.

- Size: Select from a range of standard sizes or custom sizes to fit your specific needs.

Why Choose Us

At Custom Packaging Supplier, we’re committed to providing high-quality, custom packaging solutions that meet the unique needs of the popcorn industry. Here are just a few reasons why you should choose us:

- Expertise: We have years of experience in the packaging industry, with a deep understanding of the popcorn industry’s specific needs.

- Quality: We use only the highest-quality materials and manufacturing processes to ensure your packaging is durable and protected.

- Customer service: Our dedicated customer service team is here to help you with any questions or concerns you may have.

- Loyalty program: Join our loyalty program and earn rewards for your repeat business.

By choosing our Custom Popcorn Boxes, you’ll get a custom packaging solution that is tailored to your specific needs, providing a premium presentation for your gourmet popcorn products. With our eco-friendly, sustainable materials and customization options, you can trust that your product will be presented in the best possible way. Contact us today to learn more about our custom packaging solutions and how we can help take your business to the next level.

At Custom Packaging Supplier, we offer a quick turnaround time of just 8–10 business days, ensuring your packaging is delivered on time without hassle. With low minimum order quantities starting at just 100 boxes, we make it easy and cost-effective for businesses of all sizes to get started. Our in-house design experts are here to help you create eye-catching, fully customized packaging for your Industry or any other product you need packed to perfection.

Customer satisfaction is our top priority. That’s why we provide 24/7 support to guide you every step of the way—from design advice and price quotes to order placement and delivery updates. Contact us anytime through live chat, drop us an email at sales@custompackagingsupplier.com, or call us directly at +1 (970) 333 5485. Trust Custom Packaging Supplier to deliver the quality, speed, and support your brand deserves.

Reviews

There are no reviews yet.