Description

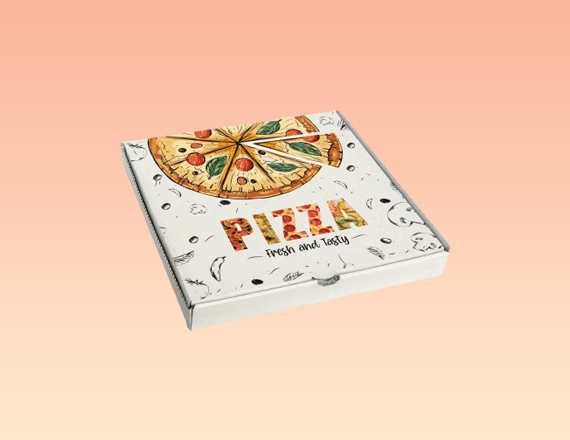

White Pizza Boxes

When it comes to packaging pies, you want a solution that protects your brand reputation and ensures your customers receive a perfectly cooked, steamy hot pizza. That’s where Custom Packaging Supplier’s White Pizza Boxes come in – designed specifically for the pizza industry, these sturdy, eco-friendly boxes keep your pies fresh and your customers satisfied.

Features

Our White Pizza Boxes boast the following key features:

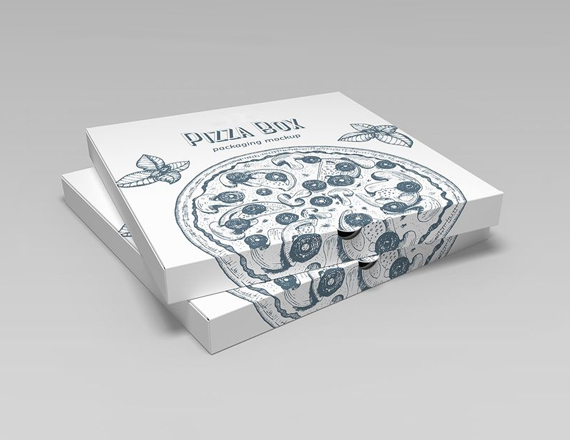

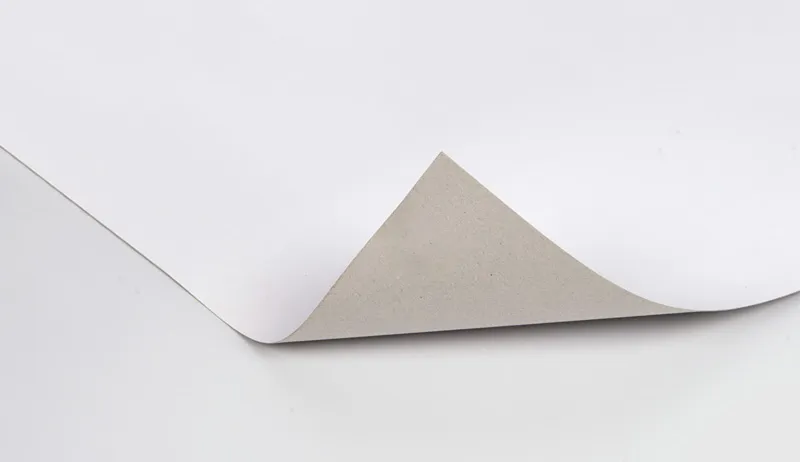

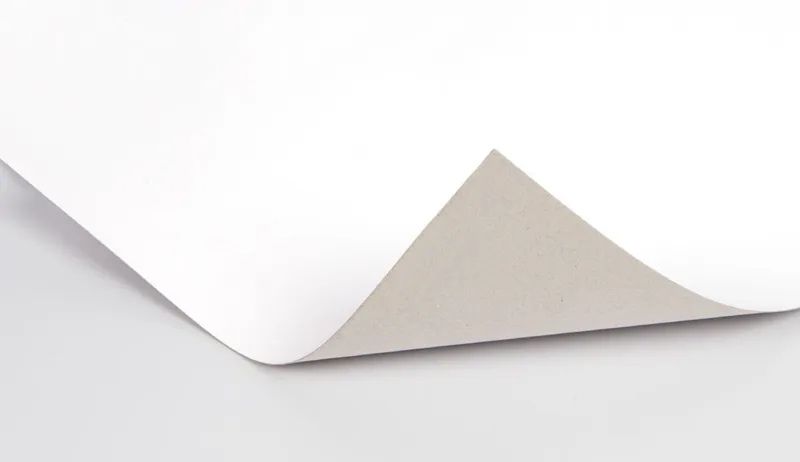

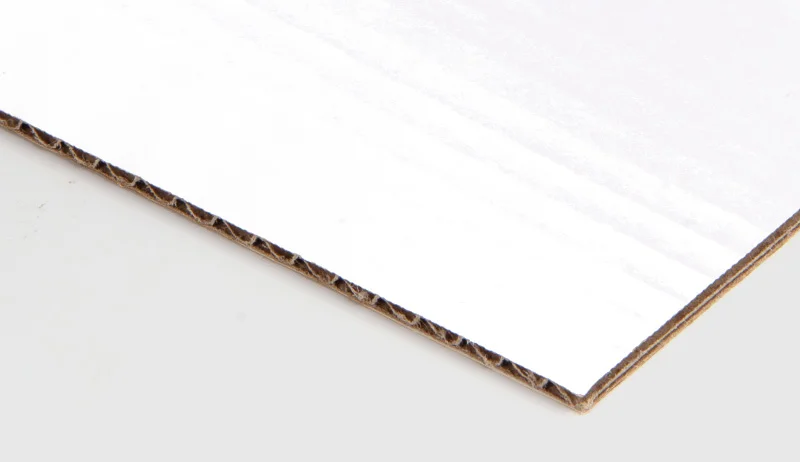

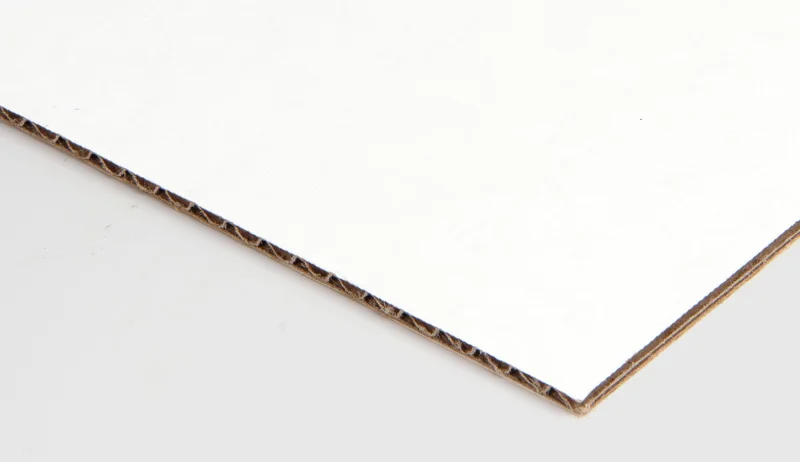

- Sturdy, kraft cardboard construction for maximum protection

- White exterior and interior surfaces for a crisp, professional look

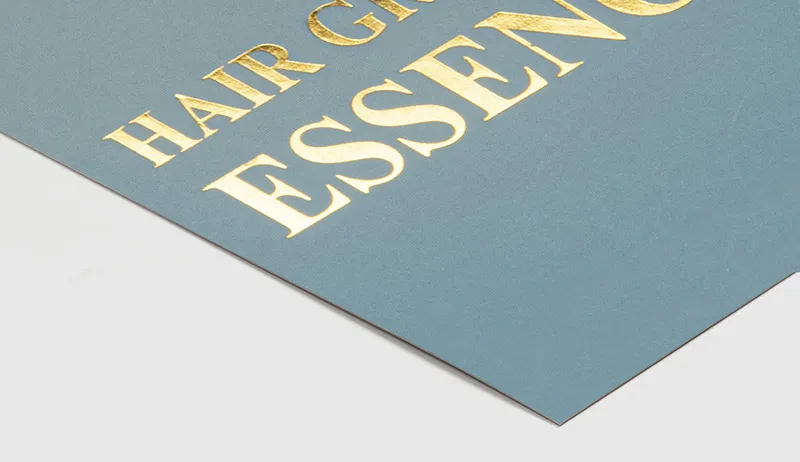

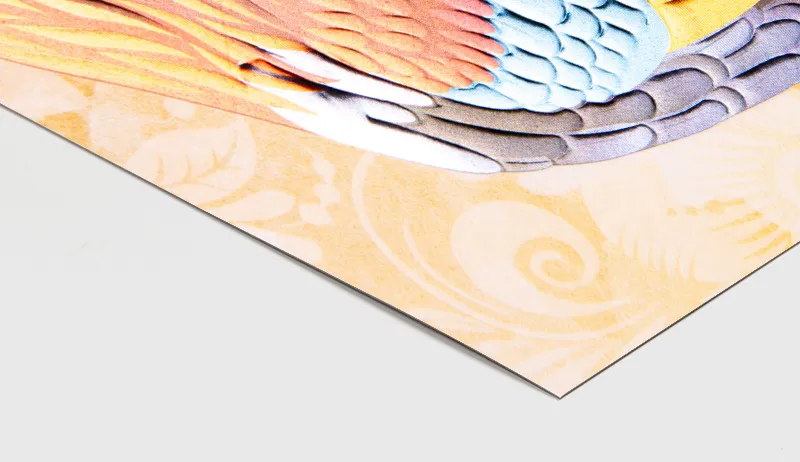

- Customizable printing options to match your brand’s unique style

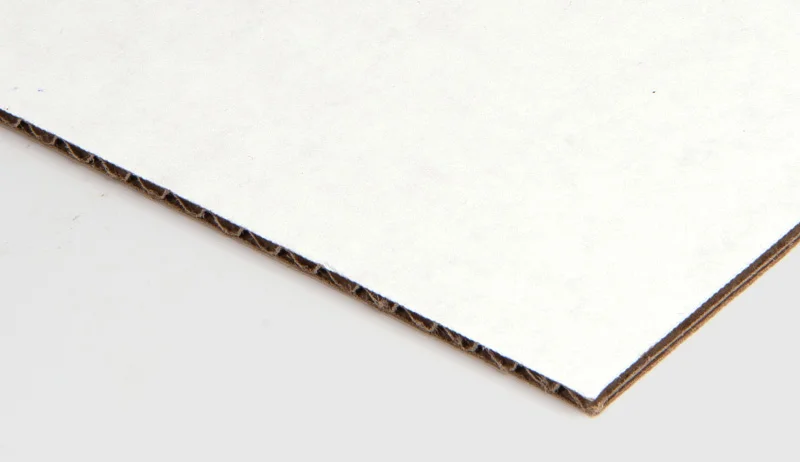

- Reinforced corrugated bottom for added durability

- Sewn, edge-to-edge blanks for enhanced protection during shipping and handling

Benefits

Why choose our White Pizza Boxes? Here are just a few compelling reasons:

Establish a strong brand identity with our customizable printing options, allowing you to promote your business and build customer loyalty.

Protect your pizzas with confidence, knowing our sturdy boxes will keep your products safe during shipping and storage.

Reduce your environmental footprint with eco-friendly, kraft cardboard construction that minimizes waste and supports sustainable practices.

Increase customer satisfaction with a refreshing, modern packaging solution that sets your business apart from the competition.

Materials

We’re committed to using only the highest-quality materials for our White Pizza Boxes. Our kraft cardboard construction is:

- Rigid and durable for maximum protection

- Eco-friendly and recyclable, reducing waste and minimizing environmental impact

- Food-grade and biodegradable for safe packaging

Use Cases

Our White Pizza Boxes are designed for various applications:

- Pizza gifts or presents for special occasions

- Store packaging for take-out, delivery, or in-store sales

- Shipping protection for transporting pizzas across distances

- Food truck or catering packaging for events and gatherings

Customization

Make your White Pizza Boxes truly unique with our customization options:

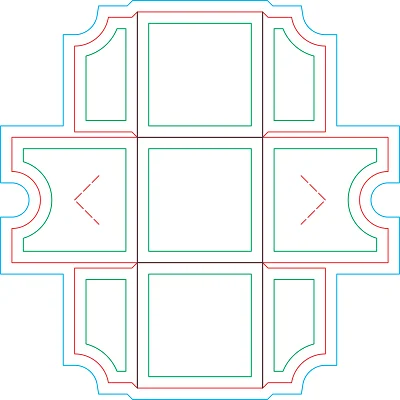

Choose from various printing processes, including flexo, gravure, and offset printing

Pick from a range of finishing options, including spot varnishing, spot coating, and UV coating

Customize box sizes to fit your specific product needs

Why Choose Us

At Custom Packaging Supplier, we’re dedicated to providing exceptional packaging solutions that meet the unique needs of our customers. With our White Pizza Boxes, you can trust that your brand is in good hands. Our commitment to quality, sustainability, and customer satisfaction ensures that you’ll receive a top-quality product that exceeds your expectations.

At Custom Packaging Supplier, we offer a quick turnaround time of just 8–10 business days, ensuring your packaging is delivered on time without hassle. With low minimum order quantities starting at just 100 boxes, we make it easy and cost-effective for businesses of all sizes to get started. Our in-house design experts are here to help you create eye-catching, fully customized packaging for your Industry or any other product you need packed to perfection.

Customer satisfaction is our top priority. That’s why we provide 24/7 support to guide you every step of the way—from design advice and price quotes to order placement and delivery updates. Contact us anytime through live chat, drop us an email at sales@custompackagingsupplier.com, or call us directly at +1 (970) 333 5485. Trust Custom Packaging Supplier to deliver the quality, speed, and support your brand deserves.

Reviews

There are no reviews yet.